7.5kw 10hp oil free screw air compressor

Advantage:

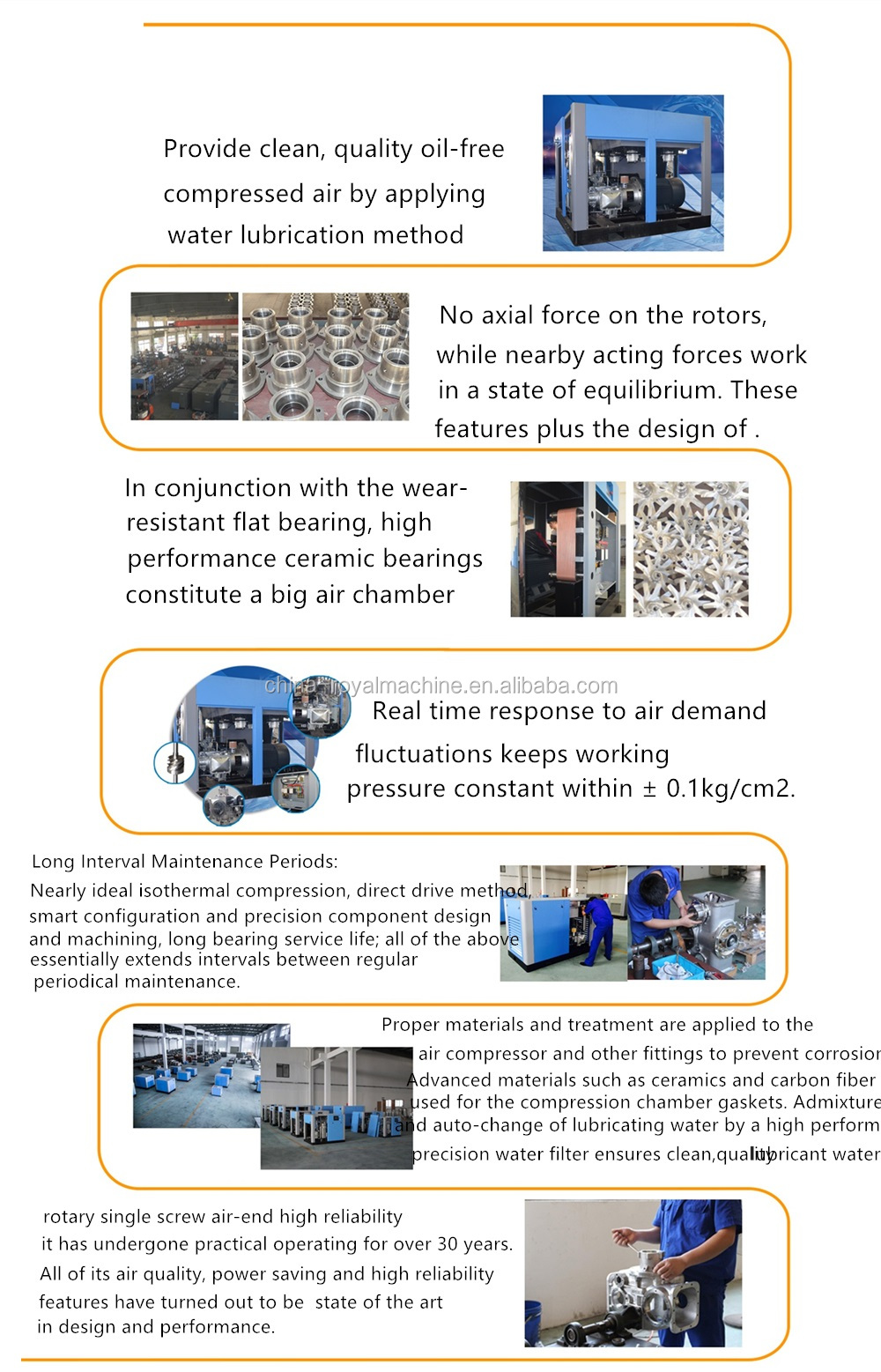

1,Oil free airend, housing and rotors stainless steel, star wheels PEEK material.

2,stainless steel material: airend housing, rotors, water separator tank, water filter assy, all pipes and valves.

3, solenoid valves, temperature sensor, water coolers are DANFOSS brand.

Application: Food industry, Fermentation,Cleaning,Instrumentation control,Medical industry...

We also offer oil free screw air end, and technical support for design and assembling oil free air end.

100% oil free water injection screw air compressor for medicine production and package use

From the production of tablets to the application of preservatives, during filling and dosing. Compressed air is usually in direct contact with the product or package. Zero-grade oil-free air prevents oil from being transferred directly to the product. For process-grade aseptic air requirements, zero-grade oil-free air is essential. Royal machinery Zero-grade 100% technology Reduced product safety issues.

8bar direct drive oil free screw air compressor

Model No.: RMW-215A

Air capacity: 2.4m3/min @ 8bar; 2.12m3/min @ 10bar.

Power: 160kw/215hp

Lubricant water volume: 300 Liters/min

Way of cooling: Water cooling

Air outlet connect: DN100

Weight: 4500kg

Dimension: 2860x1500x1750mm

Inlet temperature: atmospheric pressure 2-40℃

Outlet temperature: Cooling water temp.+14℃

Voltage: 380v/415v/220v-3p-50hz/60hz are available

Inverter and permanent magnet motor are available also

Product Description

High reliability of oil free screw air compressor

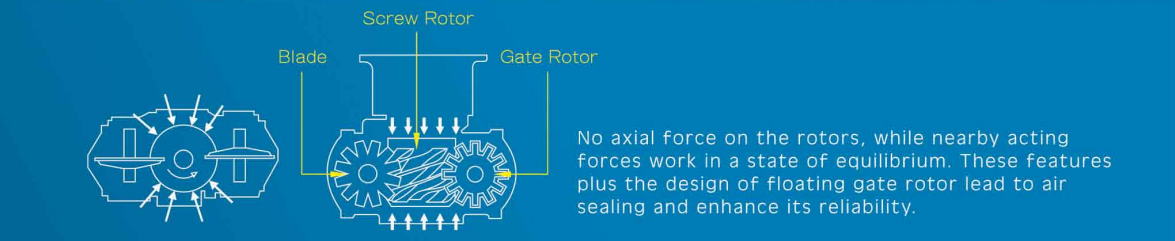

Oil free screw compressor applies rotary single screw air-end.

By being in market every since 1982, it has undergone practical for over 30 years, all of it’s air quality, power saving and high reliability features have turned out to be state of the art in design and performance.

Air and water are becoming a major trend in compressor market due to their high compatibility, availability, reliability and environment friendliness.

High efficiency (lubricated water)

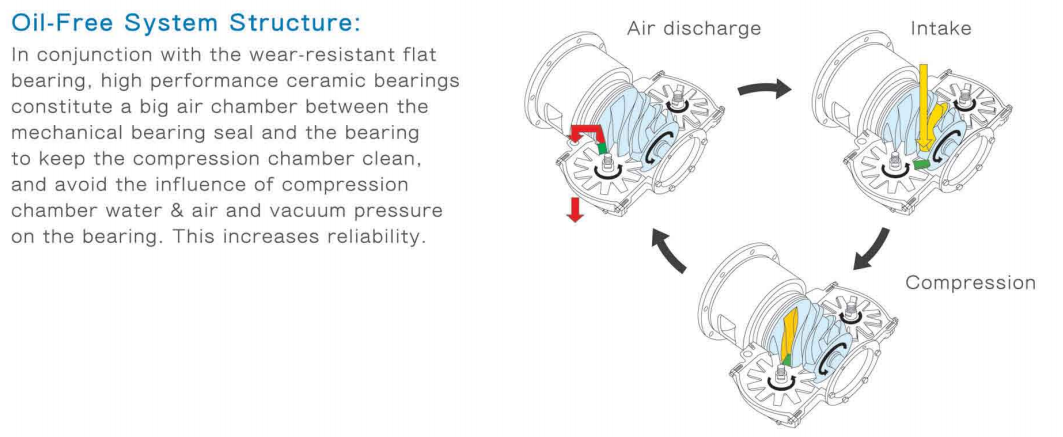

Lubricant water functions

Serves as sealant, coolant and lubricant.

Sealing function reduces/seals “blow hole” between rotors and housing to absolute minimum, ensuring efficient compression with delivered air volume per horse power increased by 15% as compared to general dry-type screw units.

Lubricant water also very effectively absorbs and dissipates heat generated during compression process.

Near isothermal compression(oil free water lubricant screw air compressor):

Thermal energy and water film, arising from the compressed air cooled by the lubricant water that has being injected into the compression chamber, seals up rotor gaps to prevent air back flow. The ideal isothermal compression thus achieves optimum efficiency. Theoretically, when air at 20℃ is compressed to 7kg/cm2G in a thermal isolation process, the discharge air temperature will be over 250℃, injection of lubrication water that has a cooling effect, into the compression chamber will bring the temperature down to about 40℃, achieving high efficiency ideal isothermal compression.

Oil free water lubricant screw air compressor--Technical parameters

| Model | Way of Transmission | Air flow /Pressure | Power | Lubricated water volume | Cooling water volume | Way of Cooling | Speed | Outlet size | Weight | Diemention (mm) | ||||

| m3/min/bar | KW | HP | L/min | L/min | rpm | Kg | L | W | H | |||||

| RMW-10A | Coupling | 1.16/8 | 1.04/10 | 7.5 | 10 | 27 | Air | 2930 | G1'' | 500 | 1300 | 800 | 1300 | |

| RMW-15A | Coupling | 1.56/8 | 1.36/10 | 11 | 15 | 27 | Air | 2930 | G1'' | 540 | 1300 | 800 | 1300 | |

| RMW-20A | Coupling | 2.4/8 | 2.12/10 | 15 | 20 | 27 | Air | 2930 | G1'' | 650 | 1600 | 910 | 1350 | |

| RMW-25A | Coupling | 3.1/8 | 2.62/10 | 18.5 | 25 | 27 | Air | 2940 | G1'' | 840 | 1600 | 910 | 1350 | |

| RMW-30A | Coupling | 3.5/8 | 3.13/10 | 22 | 30 | 27 | Air | 2940 | G1'' | 870 | 1950 | 1050 | 1432 | |

| RMW-40A | Coupling | 5.0/8 | 4.2/10 | 30 | 40 | 40 | Air | 2940 | G1 1/2" | 980 | 1950 | 1050 | 1432 | |

| RMW-50A | Coupling | 6.1/8 | 5.22/10 | 37 | 50 | 40 | Air | 2940 | G1 1/2" | 1000 | 2150 | 1300 | 1590 | |

| RMW-60A | Coupling | 7.3/8 | 6.13/10 | 45 | 60 | 40 | Air | 2960 | G2'' | 1060 | 2150 | 1300 | 1590 | |

| RMW-75A | Coupling | 9.6/8 | 8.6/10 | 55 | 75 | 100 | 150 | Water | 2960 | G2'' | 1250 | 2150 | 1300 | 1590 |

| RMW-100A | Coupling | 12.5/8 | 11.42/10 | 75 | 100 | 100 | 200 | Water | 2960 | G2'' | 1480 | 2150 | 1300 | 1590 |

| RMW-125A | Coupling | 16.3/8 | 14.52/10 | 90 | 125 | 180 | 250 | Water | 2970 | DN80 | 2030 | 2550 | 1400 | 1605 |

| RMW-150A | Coupling | 19.4/8 | 16.9/10 | 110 | 150 | 200 | 270 | Water | 2970 | DN80 | 2450 | 2550 | 1400 | 1605 |

| RMW-175A | Coupling | 22.21/8 | 20.38/10 | 132 | 175 | 240 | 320 | Water | 2970 | DN80 | 2850 | 2550 | 1400 | 1605 |

| RMW-215A | Coupling | 25.0/8 | 24.0/10 | 160 | 215 | 280 | 360 | Water | 2970 | DN100 | 3500 | 2800 | 1850 | 2000 |

| RMW-250A | Coupling | 28.0/8 | 25.0/10 | 185 | 250 | 280 | 360 | Water | 2970 | DN100 | 4000 | 2800 | 1850 | 2000 |

| RMW-270A | Coupling | 33.0/8 | 27.0/10 | 200 | 270 | 320 | 400 | Water | 2970 | DN100 | 4500 | 2800 | 1850 | 2000 |

| RMW-340A | Coupling | 41.0/8 | 38.0/10 | 250 | 340 | 320 | 400 | Water | 2970 | DN100 | 5000 | 2800 | 1850 | 2000 |

Application of screw air compressor in textile industry

When choosing the lubrication method of the air compressor, the choice should be made according to the overall situation of the enterprise. Generally, oil-free air compressors should be selected for weaving filaments and fine-grain high-density fabrics; oil-free air compressors can be used for short fiber and medium-thick fabrics, but a precision filter system needs to be installed to remove the oil in the compressed air.

Welcome to know more about water injection screw air compressor:

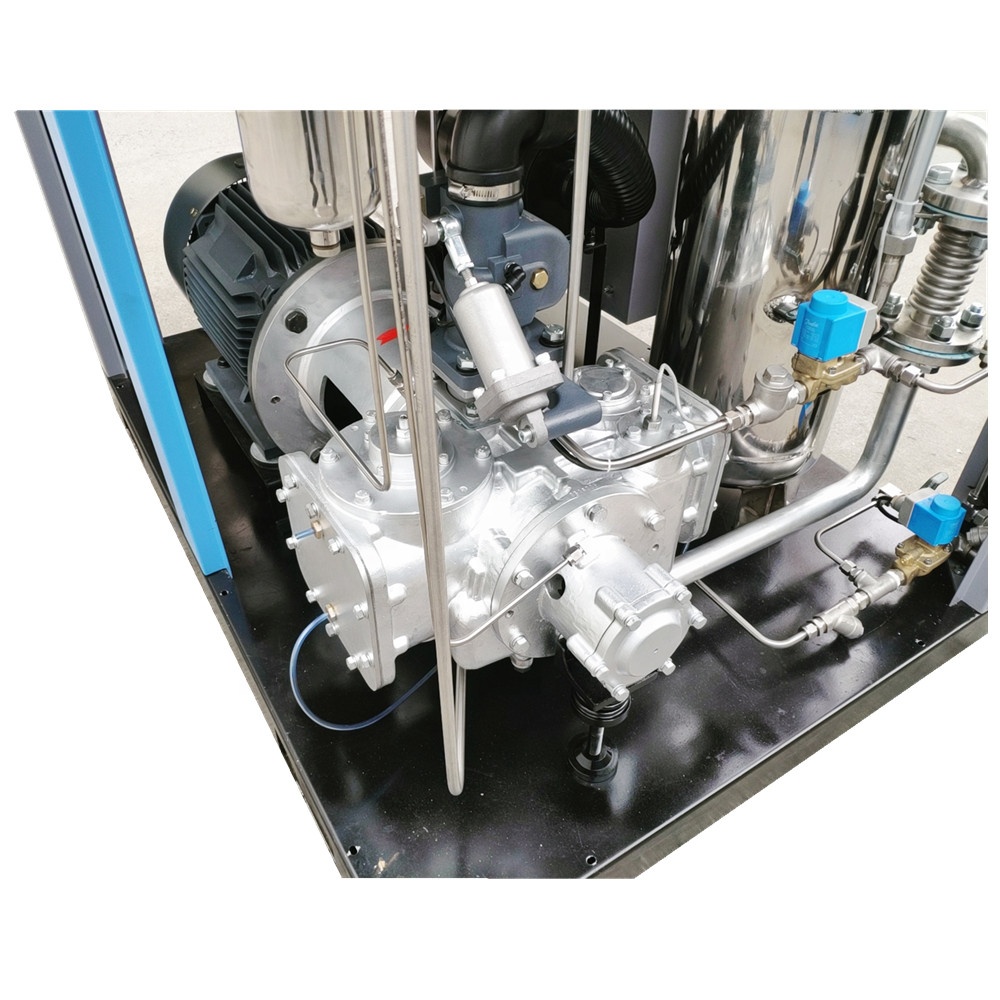

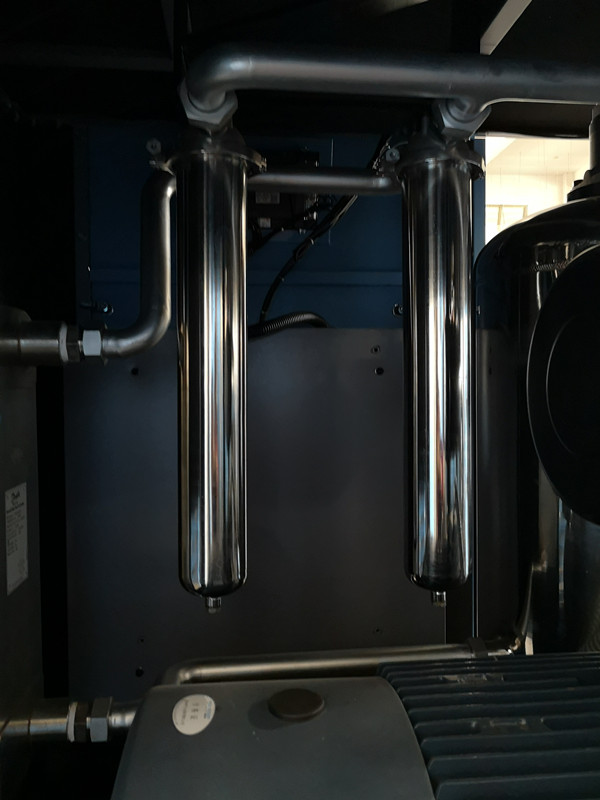

Photos: Oil free water lubricant screw air compressor

We designed and manufacture oil free screw air end by own factory:

Air cooling oil free screw air compressor flow chart:

Water cooling oil free screw air compressor flow chart:

Application--oil free water lubricant screw air compressor:

Food industry

Fermentation

Cleaning

PET, Transport

Medical industry etc.

Our Services

Long interval maintenance periods:

Nearly ideal isothermal compression, direct driven method, smart configuration and precision component design and machining, long bearing service life, all of the above essentially extends interval between regular periodical maintenance.

Company Information

Shanghai Royal Machinery Co.,Ltd is a high-tech enterprise which specialized in sales and service of compressed air system equipment, and after-treatment equipment, booster compressor, diesel generator and drying equipment, etc.

We have an experienced team. It not only provide high-quality and high-efficiency compressors for users but also provide the best solution for air system equipment during before-sale, selling and after-sale.

Welcome to contact us for inquires and quotation.

Packaging & Shipping

All of our screw air compressors are packed by export standard plywood case:

Because of screw air compressor package volume and weight, most of our screw air compressors are shipped by sea.

Categories

Contact Us

- +86-17301863604

- +86-21-59989099

- +86-17301863604

- aircompressor01@outlook.com

- susansusan258

- +86-15800773412

售前客服

售前客服