News

RMC-110BS/0.4 110kw 0.4bar oil free screw air blower

RMC-110BS/0.4 110kw 0.4bar oil free screw air blower

Oil free 40kpa 60kpa 80kpa 110kpa 150kpa low pressure screw air blower

Applications:

1.Wastewater treatment:

In many areas of environmental protection and industrial production, blower products that provide low-pressure air are required. In the field of environmental protection, rod blowers are used for both waste water discharge and air discharge. Water is vital to the never-ending life of our planet; it requires purification and recycling of waste water. Reliability, flexibility, and energy efficiency are vital factors; screw blowers provide all of these features. It is a solid, flexible variable that adapts to a wide range of air speed driven fan flow requirements. Its high level of energy efficiency limits energy costs, which typically account for 70% of total costs. Operating costs of water treatment plants

Application 2: For pneumatic conveying, you need a heavy-duty blower that can handle blockages in powder conveyance and true variable system requirements. The screw blower is a powerful blower that will serve you for years with minimal downtime. Pneumatic conveying products are expensive. Energy costs account for about 80% of the fan's life cycle cost. Therefore, high energy efficiency levels and low maintenance costs of the fans will reduce the cost of the final product.

Application 3: The textile industry runs continuously 24 hours a day, 7 days, but changes the process mode. The screw blower is easy to handle the demand for adjusting the air volume to affect whether the loom is in the most energy-saving state. It takes full advantage of the high efficiency of some permanent magnet motors. The ceiling of the screw blower is carefully designed to ensure a low noise level.

Application 4: Fermentation, desulfurization and denitration, air knife, texturing

Applications in industrial engineering such as bioengineering, pharmaceuticals, cement, steel, power generation, food processing, and textiles will also use oil-free screw blowers.Efficient oil-free collapsing fans can be applied in many industrial fields, thus providing national The economic unit's output value reduction makes its important contribution.

Features:

1.High process uptime and low life cycle costs

Energy costs can add up to 80% of the turbine life cycle cost. That's why we continue to develop new fan models that consume the lowest energy levels. Dehaha oil-free screw blowers are driven by our internally developed liquid. Cooling permanent magnet motors. Combined with a VSD inverter, this successful energy-saving variable-speed drive solution operates trouble-free in the harshest environments.

Comparison of Oil-free Screw Blower and Roots Blower

At present, Roots blowers are still widely used in various industries. In the past, its simple and reliable design solved the process application problems in various fields and made its application contribution to economic development. However, its inherent characteristics of high noise and high energy consumption are incompatible with the environment of energy conservation and environmental protection. Oil-free screw technology brings efficient and environmentally friendly blower products, which will gradually replace the outdated technology of Roots blowers.

As shown in the figure, the blue area is a comparison of the functional consumption of the screw blower and the roots blower.

In practice, the higher the pressure required by the equipment, the more significant the energy saving effect of the screw blower; at 0.5 bar pressure, the energy saving reaches 25%, and at 0.8 bar pressure, the energy saving can reach 35%.

Oil free blower save energy35%

2,The most energy efficient variable speed drive fan on the market

Take the next step in developing energy-efficient and low-voltage solutions. Comprehensive introduction of permanent magnet motors with the best energy saving effect Variable speed drive oil-free screw fans on the market.

3,Durable and reliable design

For us, every design choice is made by a reliable and durable solution. Our permanent magnet motor housing is expected to have a liquid-cooled jacket to keep it in

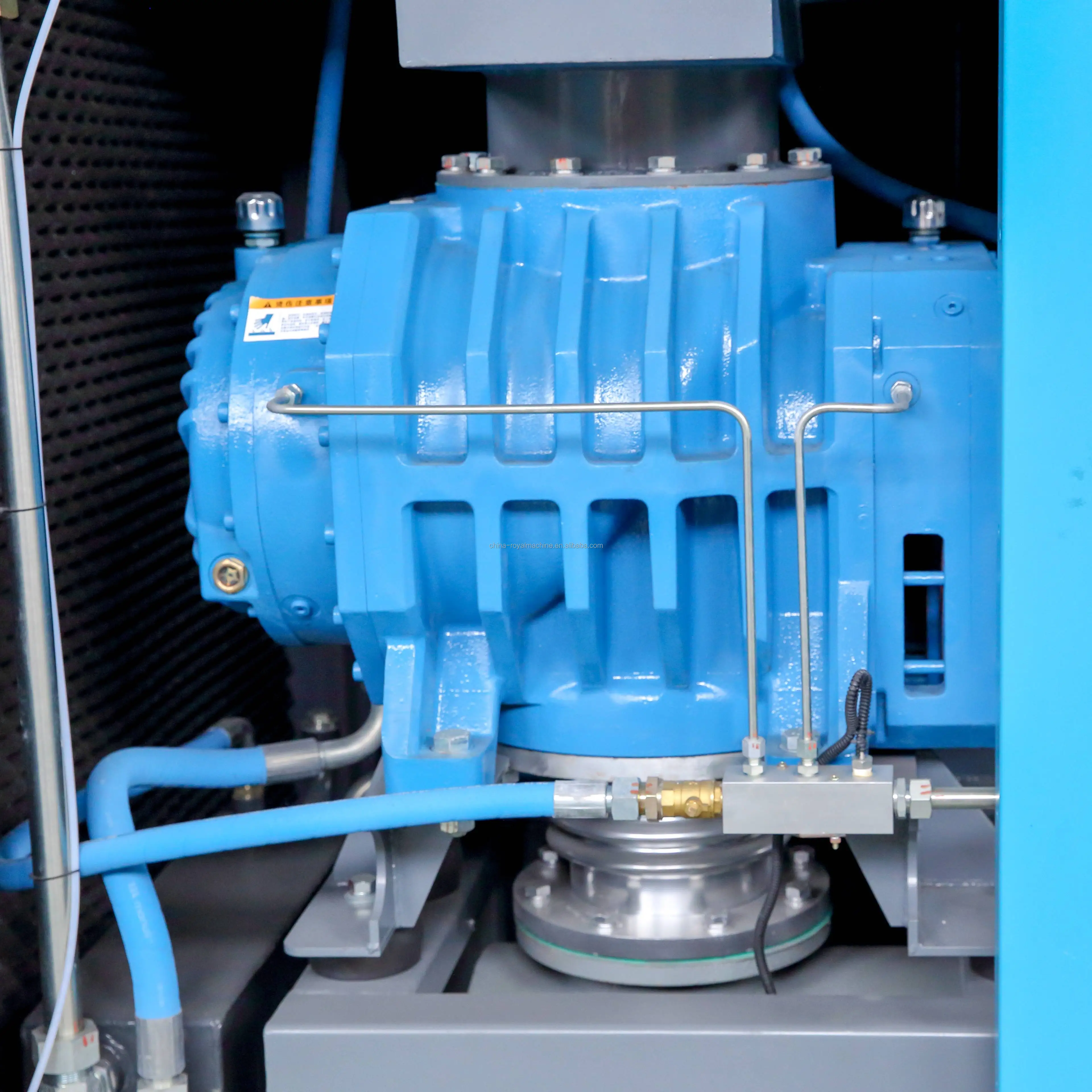

The oil-free screw compressor technology that has been fully verified by the market is applied to the field of blowers with lower pressure. The technology is mature without any pressure at all. The design and manufacturing experience of oil-free screw compressors has also made oil-free screw blowers with stable and reliable quality. Screw fans derived from oil-free screw compression technology have excellent performance and attractiveness.

Any case. Ensure that the proper amount of cooling oil is delivered to the bearings and gears. Ensure process uptime.

4,Ensure process quality and process uptime

Choose the highest guaranteed oil-free air delivery with 100% pure level 0 certification. Fully operable, the intelligent monitoring system allows you to inform the health status of the machine online and proactively propose services.

Main parameter list of our oil free screw air blowers:

| Model | Power | Pressure(bar/kpa) | Air Delivery (m³/min) | Pipe Diameter | Dimension(mm) | Weight |

| (kW) | (kg) | |||||

| RMC-5.5BS/0.4 | 5.5 | 0.4/40 | 4 | DN150 | 1400*1100*1360 | 700 |

| RMC-5.5BS/0.6 | 0.6/60 | 3.2 | ||||

| RMC-7.5BS/0.4 | 7.5 | 0.4/40 | 6.4 | DN150 | 1400*1100*1360 | 750 |

| RMC-7.5BS/0.6 | 0.6/60 | 4.6 | ||||

| RMC-7.5BS/0.8 | 0.8/80 | 3.5 | ||||

| RMC-11BS/0.4 | 11 | 0.4/40 | 8.68 | DN125 PN1.6 | 1266*980*1510 | 800 |

| RMC-11BS/0.5 | 0.5/50 | 7.4 | ||||

| RMC-11BS/0.6 | 0.6/60 | 6.2 | ||||

| RMC-11BS/0.7 | 0.7/70 | 5.6 | ||||

| RMC-11BS/0.8 | 0.8/80 | 5 | ||||

| RMC-11BS/0.9 | 0.9/90 | 4.6 | ||||

| RMC-15BS/0.4 | 15 | 0.4/40 | 11.5 | DN125 PN1.6 | 1266*980*1510 | 1200 |

| RMC-15BS/0.5 | 0.5/50 | 10.3 | ||||

| RMC-15BS/0.6 | 0.6/60 | 8.9 | ||||

| RMC-15BS/0.7 | 0.7/70 | 8.2 | ||||

| RMC-15BS/0.8 | 0.8/80 | 7.5 | ||||

| RMC-15BS/0.9 | 0.9/90 | 6.3 | ||||

| RMC-15BS/1 | 1/100 | 5.7 | ||||

| RMC-15BS/1.1 | 1.1/110 | 5.2 | ||||

| RMC-15BS/1.2 | 1.2/120 | 4.8 | ||||

| RMC-15BS/1.3 | 1.3/130 | 4.4 | ||||

| RMC-15BS/1.4 | 1.4/140 | 4 | ||||

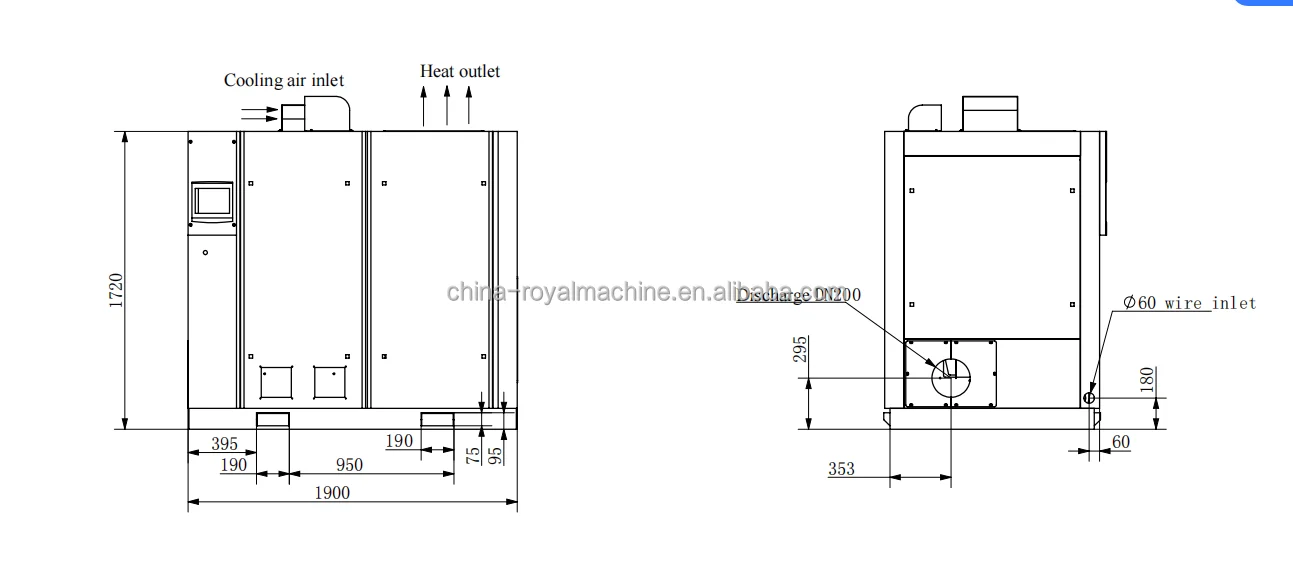

| RMC-18.5BS/0.4 | 18.5 | 0.4/40 | 21.6 | DN200 PN1.0 | 1900*1250*1720 | 1250 |

| RMC-18.5BS/0.6 | 0.6/60 | 12.1 | DN125 PN1.6 | 1266*980*1510 | ||

| RMC-18.5BS/0.7 | 0.7/70 | 10.05 | ||||

| RMC-18.5BS/0.8 | 0.8/80 | 9.91 | ||||

| RMC-22BS/0.4 | 22 | 0.4/40 | 24.2 | DN200 PN1.0 | 1900*1250*1720 | 1500 |

| RMC-22BS/0.5 | 0.5/50 | 21.4 | ||||

| RMC-22BS/0.6 | 0.6/60 | 18.1 | ||||

| RMC-22BS/0.7 | 0.7/70 | 16.5 | ||||

| RMC-22BS/0.8 | 0.8/80 | 14.6 | ||||

| RMC-22BS/0.9 | 0.9/90 | 10 | DN125 PN1.6 | 1266*980*1510 | 1500 | |

| RMC-22BS/1.0 | 1/100 | 9.41 | ||||

| RMC-22BS/1.1 | 1.1/110 | 8.6 | ||||

| RMC-22BS/1.2 | 1.2/120 | 8 | ||||

| RMC-22BS/1.3 | 1.3/130 | 7.3 | ||||

| RMC-22BS/1.4 | 1.4/140 | 6.5 | ||||

| RMC-22BS/1.5 | 1.5/150 | 6 | ||||

| RMC-30BS/0.4 | 30 | 0.4/40 | 33.1 | DN200 PN1.0 | 1900*1250*1720 | 1650 |

| RMC-30BS/0.5 | 0.5/50 | 28.7 | ||||

| RMC-30BS/0.6 | 0.6/60 | 25.92 | ||||

| RMC-30BS/0.7 | 0.7/70 | 23.1 | ||||

| RMC-30BS/0.8 | 0.8/80 | 20.5 | ||||

| RMC-30BS/0.9 | 0.9/90 | 18.1 | ||||

| RMC-30BS/1.1 | 1.1/110 | 15.5 | ||||

| RMC-30BS/1.3 | 1.3/130 | 9.2 | DN125 PN1.6 | 1266*980*1510 | ||

| RMC-30BS/1.4 | 1.4/140 | 8.7 | ||||

| RMC-30BS/1.5 | 1.5/150 | 8.6 | ||||

| RMC-37BS/0.4 | 37 | 0.4/40 | 40.5 | DN200 PN1.0 | 1900*1250*1720 | 1700 |

| RMC-37BS/0.5 | 0.5/50 | 34.4 | ||||

| RMC-37BS/0.6 | 0.6/60 | 31.6 | ||||

| RMC-37BS/0.7 | 0.7/70 | 28.22 | ||||

| RMC-37BS/0.8 | 0.8/80 | 25.74 | ||||

| RMC-37BS/0.9 | 0.9/90 | 23.7 | ||||

| RMC-37BS/1.0 | 1/100 | 20.1 | ||||

| RMC-37BS/1.1 | 1.1/110 | 19.1 | ||||

| RMC-37BS/1.2 | 1.2/120 | 18.1 | ||||

| RMC-37BS/1.3 | 1.3/130 | 14.7 | ||||

| RMC-37BS/1.4 | 1.4/140 | 12.2 | ||||

| RMC-45BS/0.4 | 45 | 0.4/40 | 43.1 | DN200 PN1.0 | 1900*1250*1720 | 2100 |

| RMC-45BS/0.5 | 0.5/50 | 40.6 | ||||

| RMC-45BS/0.6 | 0.6/60 | 38.3 | ||||

| RMC-45BS/0.7 | 0.7/70 | 31.1 | ||||

| RMC-45BS/0.8 | 0.8/80 | 30 | ||||

| RMC-45BS/0.9 | 0.9/90 | 28.22 | ||||

| RMC-45BS/1.0 | 1/100 | 25.3 | ||||

| RMC-45BS/1.1 | 1.1/110 | 23.5 | ||||

| RMC-45BS/1.2 | 1.2/120 | 22 | ||||

| RMC-45BS/1.3 | 1.3/130 | 20 | ||||

| RMC-45BS/1.4 | 1.4/140 | 17.2 | ||||

| RMC-45BS/1.5 | 1.5/150 | 16.5 | ||||

| RMC-55BS/0.4 | 55 | 0.4/40 | 65.2 | DN300 PN0.6 | 2352*1500*2140 | 2150 |

| RMC-55BS/0.5 | 0.5/50 | 53 | ||||

| RMC-55BS/0.6 | 0.6/60 | 46.8 | ||||

| RMC-55BS/0.7 | 0.7/70 | 43 | DN200 PN1.0 | 1900*1250*1720 | ||

| RMC-55BS/0.8 | 0.8/80 | 38 | ||||

| RMC-55BS/0.9 | 0.9/90 | 34.6 | ||||

| RMC-55BS/1.0 | 1/100 | 30.8 | ||||

| RMC-55BS/1.1 | 1.1/110 | 28.1 | ||||

| RMC-55BS/1.2 | 1.2/120 | 25.1 | ||||

| RMC-55BS/1.3 | 1.3/130 | 25 | ||||

| RMC-55BS/1.4 | 1.4/140 | 19.5 | ||||

| RMC-55BS/1.5 | 1.5/150 | 20.2 | ||||

| RMC-75BS/0.4 | 75 | 0.4/40 | 82.1 | DN300 PN0.6 | 2352*1600*2641 | 2200 |

| RMC-75BS/0.5 | 0.5/50 | 73.5 | ||||

| RMC-75BS/0.6 | 0.6/60 | 60 | DN300 PN0.6 | 2352*1500*2140 | ||

| RMC-75BS/0.7 | 0.7/70 | 59.5 | ||||

| RMC-75BS/0.8 | 0.8/80 | 55 | ||||

| RMC-75BS/0.9 | 0.9/90 | 50 | ||||

| RMC-75BS/1.0 | 1/100 | 47.4 | ||||

| RMC-75BS/1.1 | 1.1/110 | 45 | ||||

| RMC-75BS/1.2 | 1.2/120 | 33.1 | DN200 PN1.0 | 1900*1250*1720 | ||

| RMC-75BS/1.3 | 1.3/130 | 31 | ||||

| RMC-75BS/1.4 | 1.4/140 | 29 | ||||

| RMC-75BS/1.5 | 1.5/150 | 28.2 | ||||

| RMC-90BS/0.4 | 90 | 0.4/40 | 92.1 | DN300 PN0.6 | 2352*1600*2641 | 2500 |

| RMC-90BS/0.5 | 0.5/50 | 83.5 | ||||

| RMC-90BS/0.6 | 0.6/60 | 79 | ||||

| RMC-90BS/0.7 | 0.7/70 | 75.3 | ||||

| RMC-90BS/0.8 | 0.8/80 | 65.5 | DN300 PN0.6 | 2352*1500*2140 | ||

| RMC-90BS/0.9 | 0.9/90 | 56 | ||||

| RMC-90BS/1.0 | 1/100 | 55 | ||||

| RMC-90BS/1.1 | 1.1/110 | 50 | ||||

| RMC-90BS/1.2 | 1.2/120 | 47.2 | ||||

| RMC-90BS/1.3 | 1.3/130 | 41.1 | ||||

| RMC-90BS/1.4 | 1.4/140 | 41 | ||||

| RMC-90BS/1.5 | 1.5/150 | 37.2 | ||||

| RMC-110BS/0.4 | 110 | 0.4/40 | 129.7 | DN350 PN1.0 | 3500*2255*2370 | 2550 |

| RMC-110BS/0.5 | 0.5/50 | 100 | DN300 PN0.6 | 2352*1600*2641 | ||

| RMC-110BS/0.6 | 0.6/60 | 90.4 | ||||

| RMC-110BS/0.7 | 0.7/70 | 88 | ||||

| RMC-110BS/0.8 | 0.8/80 | 80.5 | ||||

| RMC-110BS/0.9 | 0.9/90 | 77.2 | ||||

| RMC-110BS/1.0 | 1/100 | 73.5 | ||||

| RMC-110BS/1.1 | 1.1/110 | 64.2 | ||||

| RMC-110BS/1.2 | 1.2/120 | 51.5 | DN300 PN0.6 | 2352*1500*2140 | ||

| RMC-110BS/1.3 | 1.3/130 | 48.2 | ||||

| RMC-110BS/1.4 | 1.4/140 | 50.5 | ||||

| RMC-110BS/1.5 | 1.5/150 | 46.7 | ||||

| RMC-132BS/0.4 | 132 | 0.4/40 | 150 | DN350 PN1.0 | 3500*2255*2370 | 2600 |

| RMC-132BS/0.5 | 0.5/50 | 129.5 | ||||

| RMC-132BS/0.6 | 0.6/60 | 109.1 | ||||

| RMC-132BS/0.7 | 0.7/70 | 101 | DN300 PN0.6 | 2352*1600*2641 | ||

| RMC-132BS/0.8 | 0.8/80 | 97.1 | ||||

| RMC-132BS/0.9 | 0.9/90 | 83.3 | ||||

| RMC-132BS/1.0 | 1/100 | 80 | ||||

| RMC-132BS/1.1 | 1.1/110 | 75.2 | ||||

| RMC-132BS/1.2 | 1.2/120 | 64 | ||||

| RMC-132BS/1.3 | 1.3/130 | 59.6 | DN300 PN0.6 | 2352*1500*2140 | ||

| RMC-132BS/1.4 | 1.4/140 | 59 | ||||

| RMC-132BS/1.5 | 1.5/150 | 56.2 | ||||

| RMC-160BS/0.5 | 160 | 0.5/50 | 162.7 | DN350 PN1.0 | 3500*2255*2370 | 2750 |

| RMC-160BS/0.6 | 0.6/60 | 139.4 | ||||

| RMC-160BS/0.7 | 0.7/70 | 118.7 | ||||

| RMC-160BS/0.8 | 0.8/80 | 18.5 | ||||

| RMC-160BS/0.9 | 0.9/90 | 97.6 | DN300 PN0.6 | 2352*1600*2641 | ||

| RMC-160BS/1.0 | 1/100 | 92 | ||||

| RMC-160BS/1.1 | 1.1/110 | 80.2 | ||||

| RMC-160BS/1.2 | 1.2/120 | 81.8 | ||||

| RMC-160BS/1.3 | 1.3/130 | 77.3 | ||||

| RMC-160BS/1.4 | 1.4/140 | 75 | ||||

| RMC-160BS/1.5 | 1.5/150 | 68.3 | ||||

| RMC-185BS/0.6 | 185 | 0.6/60 | 162.4 | DN350 PN1.0 | 3500*2255*2370 | 3500 |

| RMC-185BS/0.7 | 0.7/70 | 139.1 | ||||

| RMC-185BS/0.8 | 0.8/80 | 128.5 | ||||

| RMC-185BS/0.9 | 0.9/90 | 118.1 | ||||

| RMC-185BS/1.0 | 1/100 | 107.9 | ||||

| RMC-185BS/1.1 | 1.1/110 | 107.6 | ||||

| RMC-185BS/1.2 | 1.2/120 | 96.5 | DN300 PN0.6 | 2352*1600*2641 | ||

| RMC-185BS/1.3 | 1.3/130 | 89.1 | ||||

| RMC-185BS/1.4 | 1.4/140 | 81.5 | ||||

| RMC-185BS/1.5 | 1.5/150 | 76.9 | ||||

| RMC-185BS/0.7 | 200 | 0.7/70 | 149.6 | DN350 PN1.0 | 3500*2255*2370 | 3600 |

| RMC-185BS/0.8 | 0.8/80 | 138.8 | ||||

| RMC-185BS/0.9 | 0.9/90 | 128.2 | ||||

| RMC-185BS/1.0 | 1/100 | 117.8 | ||||

| RMC-185BS/1.2 | 1.2/120 | 107.3 | ||||

| RMC-185BS/1.3 | 1.3/130 | 96.4 | DN300 PN0.6 | 2352*1600*2641 | ||

| RMC-185BS/1.4 | 1.4/140 | 90.5 | ||||

| RMC-185BS/1.5 | 1.5/150 | 81.3 | ||||

| RMC-220BS/0.7 | 220 | 0.7/70 | 162.1 | DN350 PN1.0 | 3500*2255*2370 | 3600 |

| RMC-220BS/0.8 | 0.8/80 | 149.3 | ||||

| RMC-220BS/0.9 | 0.9/90 | 138.5 | ||||

| RMC-220BS/1.0 | 1/100 | 127.9 | ||||

| RMC-220BS/1.1 | 1.1/110 | 117.5 | ||||

| RMC-220BS/1.2 | 1.2/120 | 117.2 | ||||

| RMC-220BS/1.3 | 1.3/130 | 107 | ||||

| RMC-250BS/0.8 | 250 | 0.8/80 | 161.8 | DN350 PN1.0 | 3500*2255*2370 | 3800 |

| RMC-250BS/0.9 | 0.9/90 | 161.5 | ||||

| RMC-250BS/1.0 | 1/100 | 148.7 | ||||

| RMC-250BS/1.1 | 1.1/110 | 137.9 | ||||

| RMC-250BS/1.2 | 1.2/120 | 127.3 | ||||

| RMC-250BS/1.3 | 1.3/130 | 116.9 | ||||

| RMC-250BS/1.4 | 1.4/140 | 106.7 | ||||

| RMC-250BS/1.5 | 1.5/150 | 106.4 | ||||

| RMC-280BS/1.0 | 280 | 1/100 | 161.2 | DN350 PN1.0 | 3500*2255*2370 | 3850 |

| RMC-280BS/1.1 | 1.1/110 | 148.4 | ||||

| RMC-280BS/1.2 | 1.2/120 | 137.6 | ||||

| RMC-280BS/1.3 | 1.3/130 | 127 | ||||

| RMC-280BS/1.4 | 1.4/140 | 126.7 | ||||

| RMC-280BS/1.5 | 1.5/150 | 126.4 |

Packaging & Shipping

Screw air compressors package Oil-free Scroll air compressors 200bar-300bar Air compressors

For our screw air compressors, we packed them by plywood case for LCL shipping, for full container shipping, we will pack the air compressors depend on customer request, sometimes by pallet too. | We packed all of our oil-free scroll air compressors by plywood case, because they take not much big space, and for good safe transport, if oil-free scroll airend, we will pack them by pp foam first, after that by plywood case. | For our small breathe air compressors,we all packed them by plywood case, normally they are 2.2kw 225bar or 330bar pressure, take very small space, for scuba diving and firefighting breathe air. |

Company Information

Shanghai Royal Machinery Co.,Ltd is a professional company of industrial air compressors, air treatment and air compressor spare parts, with engineers and sales people who have over 8 years experience, Royal Machinery has two business divisions, one is our own brand products, the other brands are Ingersoll Rand and Compair products. We have been marketing industrial compressed air equipment to global market since 2017 and the main assembling plants cover more than 50,000 square meters and 320 employees. The range of our compressors supplying start from the smallest compressors used by individuals to very large compressors used in heavy industrial applications. We started the business as a close partner to our customers, our sales team can provide you competitive price with high quality products, with our customers supporting, our team will get all the orders fulfilled on time and provide you excellent after-sales service. Our product range represents the most comprehensive portfolio of compressed air equipment offered for thousands of applications in the Oil, Textile, Food, Marine, Mining and many other industries. Our products consist of medium and high pressure reciprocating compressors, oil-injected screw compressors, oil free screw compressors, vane compressors, centrifugal compressors, portable compressors, CNG compressors and CNG related equipment, also high pressure scuba air compressors. Our mission is to bring China assembled compressors of good quality and service, with attractive price for all the customers all over the world. You are welcomed to be developed with us together for a fruitful future.

Wecome to contact us for more details, we will offer compressor details, oil free screw air compressor use manual, oil free screw air compressor configuration list, oil free screw air compressor instruction drawings, spare parts list, installation drawings, technical support and maintenance training.

FAQ

1. What's the warranty of your air compressors

we give screw airend 2 years warranty, complete compressor unit 1 year; oil-free scroll air compressors we give 2 years warranty.

2. Can you do OEM?

Yes, we accept OEM and ODM orders for all our air compressors.

3. What is the delivery time of the air compressor?

It depend on customer order quantity, for regular voltage and pressure air compressors, our lead time 7 days, if big quantity we need 10-20days to prepare.

4. What's the MOQ

We accept all of our air compressors MOQ 1 unit.

5. Can your air compressors work at high ambient temperature like 50℃ above please?

Yes, our oil injection screw air compressors are support to work at high temperature environment, for oil-free water-lubrication screw air compressors, we will design it to be with air cooling or water cooling according to ambinet temperature.

6. Can your air compressor work at low temperature like -20℃ below?

Yes our air compressor is working very good in area like North of China and Russia.

7. Do you have installation or maintenance video?

Yes, we can offer our air compressor installation and maintenance video to customers.

Categories

Contact Us

- +86-17301863604

- +86-21-59989099

- +86-17301863604

- aircompressor01@outlook.com

- susansusan258

- +86-15800773412

售前客服

售前客服